Toyota has unveiled a novel innovation for liquid hydrogen vehicles aimed at enhancing efficiency and minimizing fuel loss. The new system, showcased during the Super Taikyu Series 2024 race, incorporates a self-pressurizer that reuses boil-off hydrogen gas, a typical byproduct of liquid hydrogen storage, to increase engine performance.

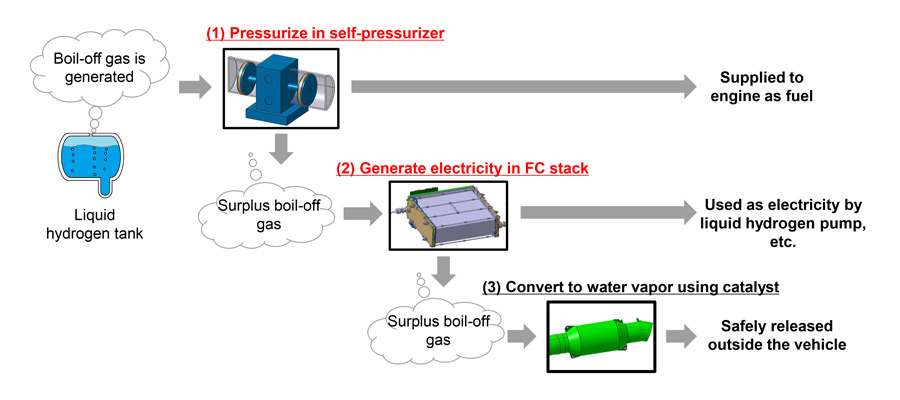

Hydrogen must be stored at extremely cold temperatures, approximately -253°C, to remain in liquid form. During storage and refueling, some of this hydrogen naturally escapes as boil-off gas, which is usually wasted. Toyota’s self-pressurizer uses this escaping gas to boost fuel pressure by two to four times without consuming additional energy. The system also channels excess boil-off gas into a small fuel cell package to power the hydrogen pump motor, creating a more efficient cycle.

The innovation builds upon Toyota’s previous experiments with liquid hydrogen systems, such as those integrated into the GR Corolla H2 Concept in 2023. This earlier model highlighted the challenges of managing liquid hydrogen, particularly the need to maintain ultra-cold temperatures and the susceptibility of hydrogen pumps to failure due to their cryogenic operating conditions.

Experts in the field have noted the significance of Toyota’s development. Dr. Jacob Leachman, a professor at Washington State University and director of the Hydrogen Properties for Energy Research (HYPER) Laboratory, explained that hydrogen pumps are a critical weak point in hydrogen systems. According to Leachman, Toyota’s design cleverly repurposes the energy inherent in cold hydrogen for compression, addressing a key technical hurdle in the development of liquid hydrogen vehicles.

Sealing a liquid hydrogen tank poses another significant challenge, as pressure can quickly escalate to over 140 Megapascals (20,000 psi) if boil-off gas accumulates. Toyota’s self-pressurizer offers a promising solution to mitigate these risks while improving overall system efficiency.

Toyota’s advancements signal progress in the quest for practical hydrogen-powered vehicles, but the technical complexities of liquid hydrogen storage and fueling remain formidable. The company’s latest innovation could set a benchmark for the next generation of hydrogen technologies.