Researchers have developed a novel material, similar to those used in dental fillings, which could significantly reduce electronic waste (e-waste).

In 2022, global e-waste amounted to 62 million metric tons, covering anything with a plug or battery. This figure is projected to increase by 32 percent, reaching 82 million metric tons by 2030, according to the United Nations Institute for Training and Research. Despite this growth, e-waste recycling is not keeping pace, with estimates suggesting only 20 percent will be recycled by 2030.

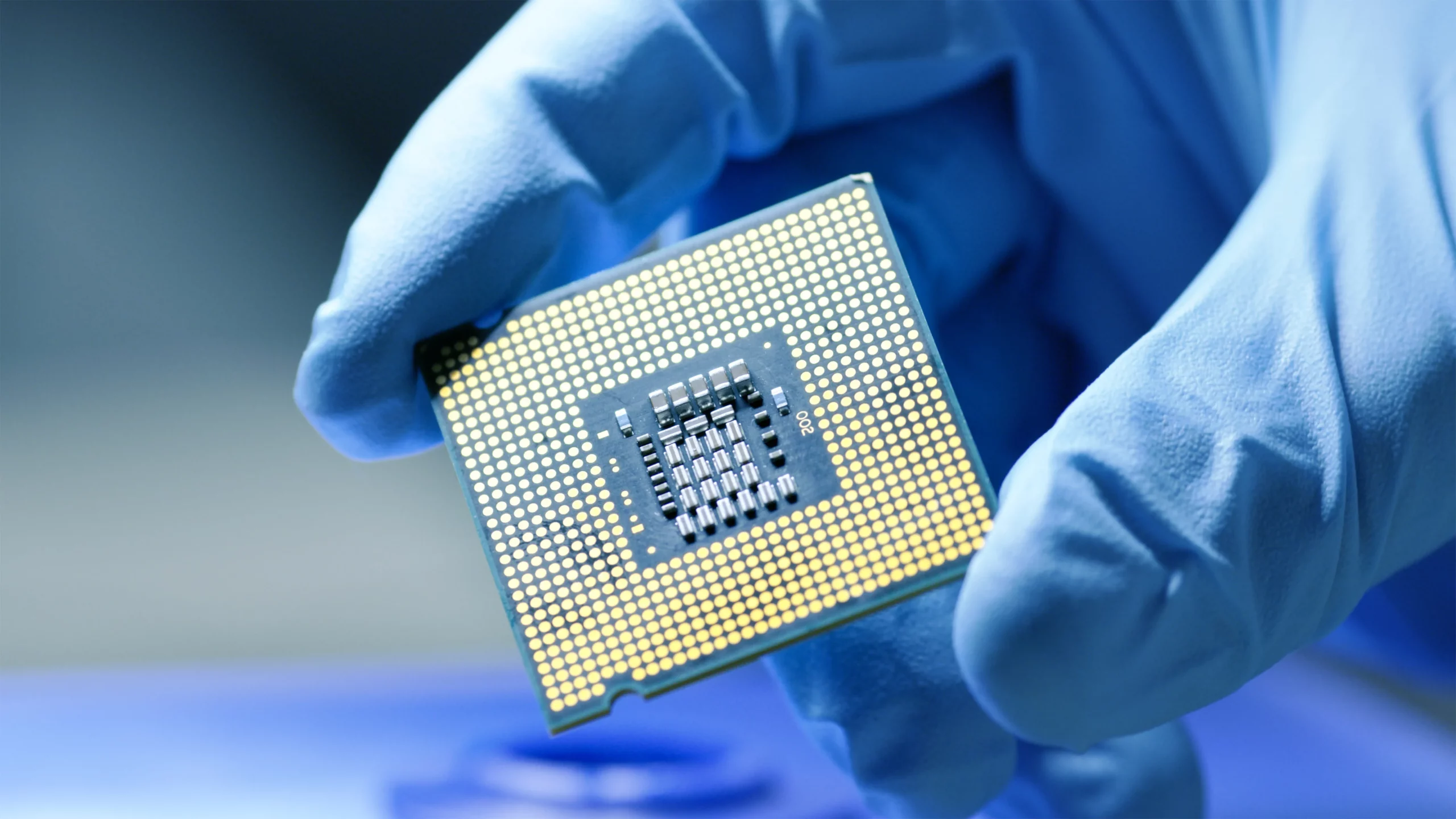

A promising development in addressing e-waste comes from a paper published in July in the journal RSC Applied Polymers. Researchers from the University of Utah, Massachusetts Institute of Technology (MIT), and Meta’s Reality Labs have created a new substrate material for computer chips and circuit boards. This material is both flexible and dissolvable, potentially allowing the reuse of attached components.

Thomas Wallin, an assistant professor in MIT’s Department of Materials Science and Engineering and coauthor of the paper, stated that this innovation will enable high-performance flexible electronic devices and help solve the e-waste issue by enabling the economic recapture of electronic components at the end of their life.

Limitations of Current Materials

Currently, a common flexible substrate is a polyimide material known as Kapton, which is a high-performance plastic used in various applications due to its thermal and insulating properties. However, Kapton cannot be easily melted or dissolved, limiting its recyclability and contributing to e-waste accumulation.

Wallin noted that although Kapton has been integral to electronic devices for decades, its insolubility prevents easy recycling and reprocessing, which hinders the advancement of scalable electronic architectures.

Where Can Flexible Electronics Be Used?

Flexible electronics are crucial for conventional technology like computers and emerging fields such as wearable tech, the internet of things, and the metaverse.

The new material developed by the researchers, similar to the polymer used in dental fillings, can be processed at low temperatures, hardens quickly, and is cured with ultraviolet light. As a type of polyimide, it is expected to be compatible with existing manufacturing processes and facilitate the creation of more complex circuit designs.

The reusability of this new substrate material becomes apparent when circuits or chips reach the end of their useful life. The material can easily dissolve under mild conditions, allowing for the recovery of valuable metals from the chips, as Wallin explained. This property could significantly impact the economic recapture of electronic components and help mitigate the growing e-waste problem.